Journey Through the History of Lab Grown Diamonds

When you think about the origins of lab-grown diamonds, you might immediately picture the high-tech laboratories of today creating stunning, high-quality, large-sized lab diamonds in a wide range of shapes and colors, but the story begins much earlier. Not in 2025, but this story takes place in the late 80s. Read this post to learn everything about the history of lab-created diamonds, from when they were invented and who invented them to what difficulties they faced back then. After many failed attempts, in which year did the researchers succeed in creating a lab-grown diamond?

If you know, lab grown diamonds were first adopted by industries such as abrasives manufacturing and electronics, where their exceptional hardness and thermal conductivity were beneficial in tools and electronic applications. But when did these early lab diamonds enter the market for commercial and jewelry use, and when did GIA approve lab diamonds with 4Cs, certifying them to have the same chemical, optical, and physical properties as natural diamonds at a fraction of the cost? Don’t worry; Finegrown is here to provide all the information you need. We have been working in this industry for the past 15 years. Let’s get started!

History of Lab Grown Diamonds

Discovery of the First Synthetic Diamonds

The story of lab-grown diamonds and diamond simulants begins long before the first successful creation. In the early stages of creating a diamond made by humans, the founding figure of modern chemistry, Antoine Lavoisier, played an important role in making synthetic diamonds. He has discovered that diamond’s crystal lattice is similar to carbon’s crystal structure, paving the way for initial attempts to produce diamonds. After that, in 1797, British chemist Smithson Tennant made a groundbreaking discovery: diamonds are composed entirely of pure carbon. This revelation was pivotal, as it inspired generations of scientists to explore ways to recreate diamonds artificially.

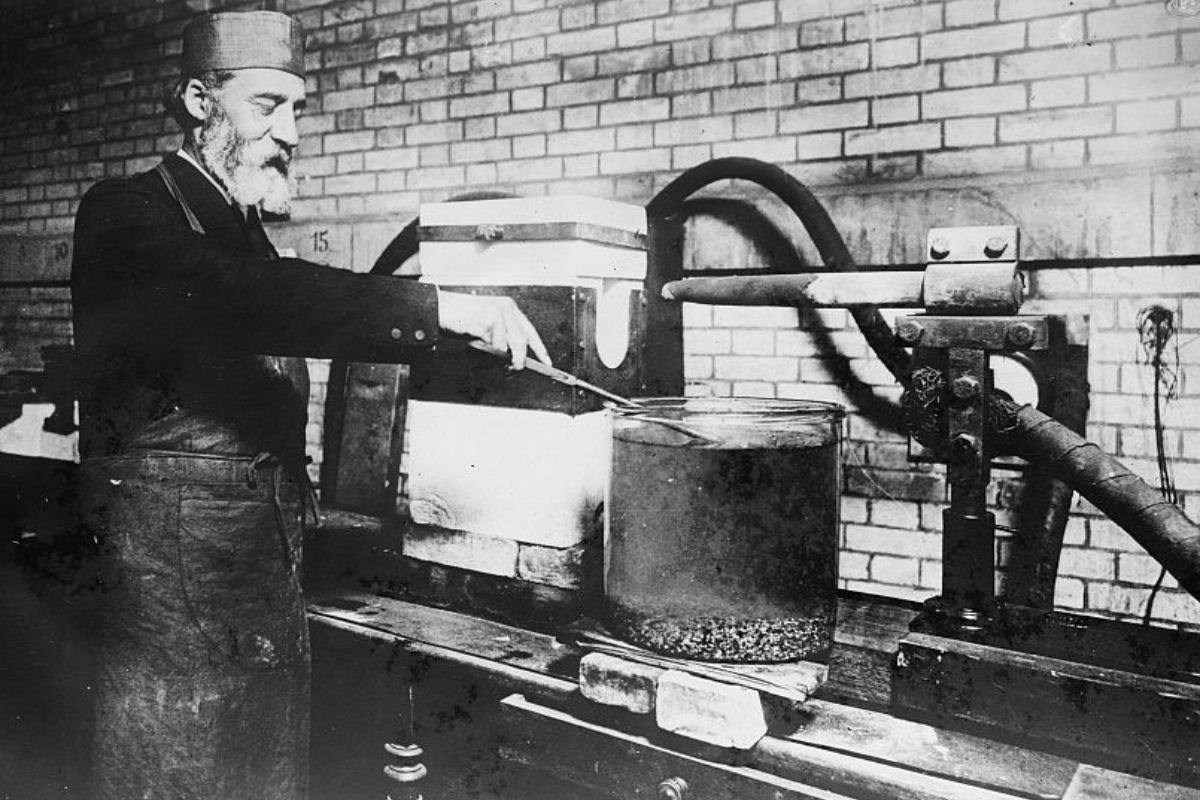

By the late 19th century, the ambition to synthesize diamonds had gained serious attention. In 1879, James Ballantyne Hannay of Scotland claimed to have produced diamonds by heating carbon in iron tubes under high pressure. A few years later, in 1893, Ferdinand Frédéric Henri Moissan of France made similar claims after using an electric arc furnace to mimic extreme heat and pressure conditions, which would pave the way for future advancements and customization options in diamond synthesis.

While both experiments lacked reproducible results and were never scientifically confirmed, they marked the earliest attempts to imitate nature’s diamond-forming process, laying the scientific foundation for future breakthroughs.

Early Attempts at Synthesis

The 20th century brought renewed energy and technological progress to diamond synthesis. By the early 1940s, researchers had begun developing advanced high-pressure and high-temperature (HPHT) equipment capable of recreating the natural environment in which diamonds form, highlighting the future of the diamond industry.

General Electric (GE), one of the earliest industrial leaders to explore diamond creation, began research in 1941. However, the onset of World War II forced the company to pause its experiments. After the war, GE reassembled its research team and resumed its efforts to convert carbon into diamond through controlled pressure and temperature methods.

Meanwhile, in Sweden, the ASEA Company was conducting similar research. On February 16, 1953, ASEA scientists quietly succeeded in producing small synthetic diamonds using their own HPHT apparatus. However, their success was kept secret for decades and only revealed publicly in the 1980s.

This era marked a turning point; diamond synthesis had officially moved from theoretical science to practical experimentation.

Who First Invented Lab-Grown Diamonds?

The true breakthrough came shortly after ASEA’s hidden success. On December 16, 1954, General Electric (GE) announced that its research team, with Francis P. Bundy and Herbert Strong. Later, Howard Tracy Hall and others joined the project and gave it the right path.

In the lab, they had successfully produced replicable synthetic diamonds from a diamond seed. Hall and his colleagues successfully converted carbon into diamond by using pressures greater than 100,000 atmospheres and temperatures greater than 1,600°C using the HPHT process.

This accomplishment was the first man made diamond production to be confirmed by the public. Small and of industrial quality, the original stones were mostly utilized for cutting and drilling instruments and industrial purposes such as cutting, drilling, and polishing, because they lacked the clarity and color needed for fine jewelry. But by the 1970s, advancements in technology made it possible to produce gem-quality diamonds that played a significant role in being optically identical to those that were mined from the Earth’s crust.

In addition to proving that diamonds could be created in a lab, GE’s breakthrough transformed the diamond market. It cleared the path for more advancements, such as Chemical Vapor Deposition (CVD) in subsequent decades, a technique that still influences the market for lab grown diamonds today, allowing for the formation of a diamond layer during the growth process.

The Commercialization of Lab Grown Diamonds: 1980s to Early 2000s

The journey toward commercialization began much earlier than most realize. In 1971, the Gem Society recorded the creation of the first gem-quality lab diamond, a milestone that laid the foundation for future grading systems and widespread acceptance. Building on this breakthrough, the 1980s marked a major turning point as technological advances made large-scale diamond synthesis more efficient and consistent.

By the early 2000s, lab-created diamonds had entered the global jewelry market, promoted as ethical, eco-friendly, and affordable alternatives to mined diamonds. With further innovation, improvements in quality, size, and color range made them a mainstream favorite, especially for engagement rings and luxury fine jewelry.

The Rise of Sustainability and Ethical Concerns: 2010s

A significant shift occurred in the diamond industry during the 2010s, as sustainability and ethical sourcing became increasingly important to consumers. The increasing awareness of the environmental damage caused by traditional diamond mining and its association with conflict diamonds has propelled the demand for lab-grown alternatives. These diamonds, produced using processes like chemical vapor deposition, offered an affordable solution without compromising on quality or physical properties. Diamond Companies began promoting lab diamonds as conflict-free, tapping into a growing market of eco-conscious buyers seeking unique engagement rings. This era marked the emergence of innovative manufacturing processes, elevating the status of lab-grown diamonds within fine jewelry and the global diamond market.

Certification and Grading: GIA Guaranteeing Quality and Authenticity

Ensuring the quality and authenticity of lab-grown diamonds involves a meticulous certification and grading process, and no organization plays a more trusted role than the Gemological Institute of America (GIA). Since 2007, GIA has been grading laboratory-grown diamonds with the same scientific precision applied to natural ones. In a significant shift, beginning July 1, 2019, GIA updated its terminology to reflect transparency and modern understanding, removing the word “synthetic” from all its laboratory-grown diamond reports, enhancing the entire production process of these gems.

Each GIA Laboratory-Grown Diamond Report now includes the institute’s renowned color, clarity, and cut grading scales, offering consistent benchmarks that help establish a diamond’s value and authenticity. Rather than using numeric grades, the reports use descriptive terms to indicate these qualities, ensuring clarity for both consumers and retailers.

Bridal Trends and Lab Grown Diamonds: A Modern Engagement

Lab-grown diamonds began gaining popularity for engagement rings in the early 2010s, when technological advances made them visually and chemically identical to mined diamonds while remaining significantly more affordable.

By around 2015, consumer awareness and demand surged, driven by sustainability concerns, ethical sourcing, and the entry of major jewelry brands offering lab-grown diamond engagement rings.

Their popularity skyrocketed further after 2018, when leading certification bodies like GIA and IGI began issuing standardized grading reports for lab-grown diamonds, boosting consumer confidence. Today, lab-grown diamonds have become a mainstream and desirable choice for engagement rings, blending luxury, ethics, and value.

Availability of Lab Diamonds in Varying Quality and Sizes

Over the years, advanced technologies and improved production methods have significantly enhanced the quality of lab made diamonds. Modern advancements in both HPHT (High Pressure High Temperature) and CVD (Chemical Vapor Deposition) techniques have enabled the growth of larger, purer crystals than ever before. Today, laboratories are capable of manufacturing lab grown diamonds up to 30 carats, depending on technological precision and the specific requirements of a client. However, for jewelry purposes, a 10-carat lab diamond is generally considered more than sufficient, offering exceptional brilliance and size without compromising quality.

In fact, one of the most notable scientific milestones in diamond growth is the creation of a single, freestanding, unpolished lab-created diamond crystal weighing 155 carats, showcasing the immense potential of modern technology in controlled diamond synthesis. Although such record-breaking crystals are not gem-quality, they symbolize just how far the industry has advanced, especially when considering the comparisons with real diamonds.

These lab-grown diamonds, available in premium quality, can now be set in engagement rings and fine jewelry, giving the wearer a stunning and sophisticated look. Not only size but also the clarity, color, and cut precision of lab-made diamonds have improved dramatically over time. Today, buyers can choose from a wide range of high-quality options, all visually and chemically identical to mined diamonds, yet offered at a more affordable price, as they eliminate the environmental and mining costs associated with natural diamond extraction, making them a popular choice for modern consumers.

FAQs:-

What inspired scientists to create lab created diamonds in the first place?

The inspiration came from both scientific curiosity and industrial need. In the late 19th and early 20th centuries, scientists wanted to understand how nature formed diamonds and replicate those conditions. Meanwhile, industries required super-hard materials for cutting and drilling, a demand that natural diamond scarcity couldn’t meet affordably.

Were lab grown diamonds ever kept secret or restricted for industrial use?

Yes. For decades, synthetic diamonds were considered industrial innovations and not luxury items. Early successes, like those by ASEA in Sweden during the 1950s, were kept confidential due to commercial competition and patent interests, only being revealed years later when gem-quality production became viable.

Did any celebrity endorsements help boost lab grown diamond popularity?

Absolutely. Several Hollywood and fashion icons began wearing lab-grown diamond jewelry on red carpets around 2018–2020, normalizing them as elegant and ethical diamonds alternatives. Their endorsement helped lab-grown diamonds become part of mainstream bridal and fashion jewelry trends.

Which country leads in lab diamond production today?

China currently dominates 40% to 56% of the global market for the production of lab grown diamonds using hpht method. After China, India has become the world’s hub for particularly in the cutting, polishing, and export of lab-grown diamonds, contributing to its global expansion.